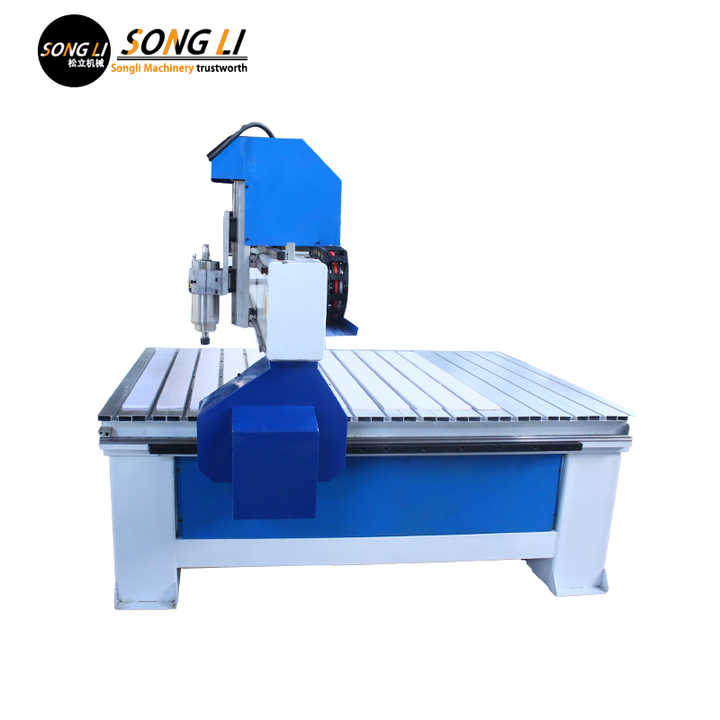

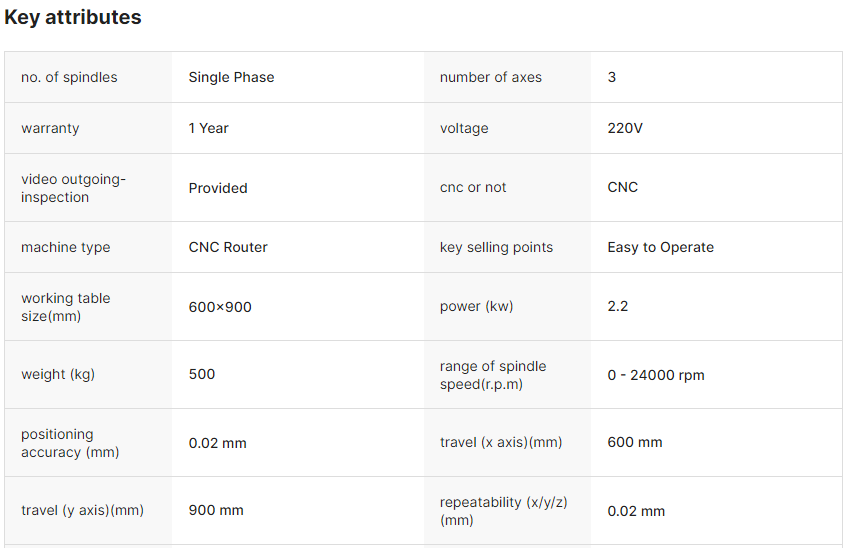

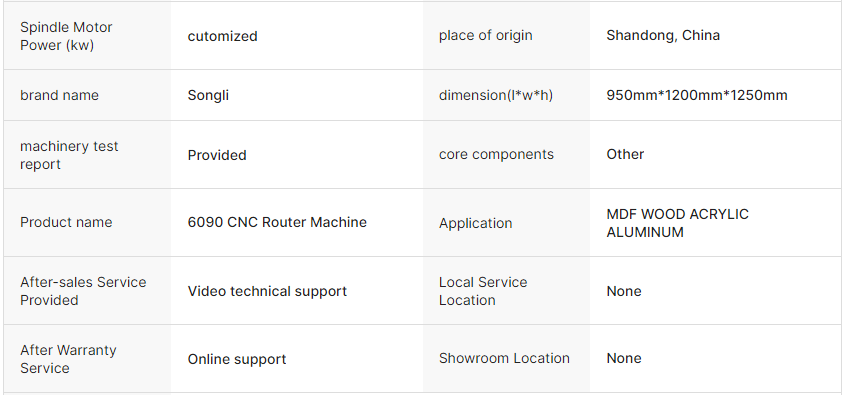

Operating the Wood MDF Drilling Cutting Machine (models 6090, 6015, 9012) with Mach3 CNC system is straightforward.

First, power on the machine and launch the Mach3 software on your connected computer. Load the design file (compatible with formats like .dxf or .gcode) into the software, then secure the wood or MDF material firmly on the worktable using clamps to prevent movement during processing. Next, calibrate the machine’s origin point—use the manual jog function in Mach3 to position the spindle tip at the desired starting point (usually the corner of the material) and set it as the X, Y, Z zero. Adjust spindle speed and feed rate in the software based on the material thickness and task (drilling, cutting, or 3D sculpture). Once settings are confirmed, click "Cycle Start" in Mach3 to begin the operation. Monitor the process to ensure smooth running; pause or stop via the software if any issues arise. After completion, power off the machine and remove the finished piece.