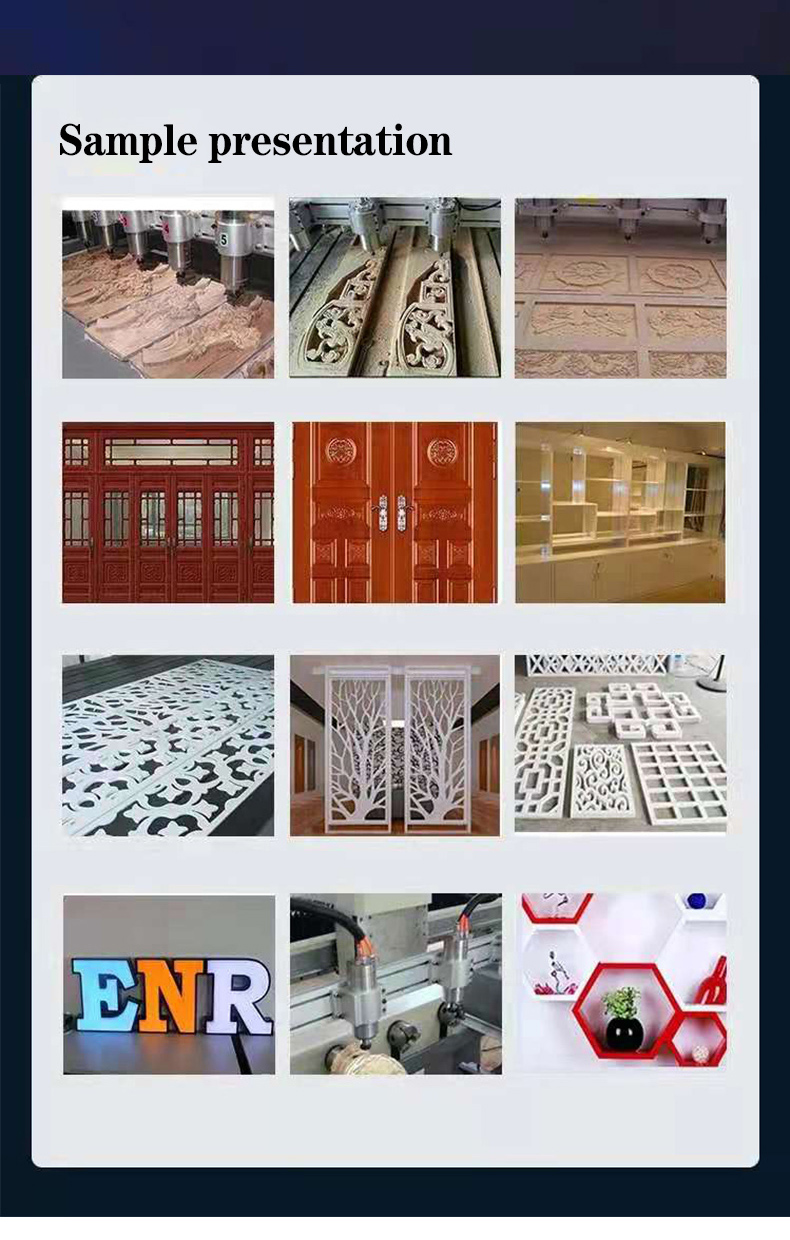

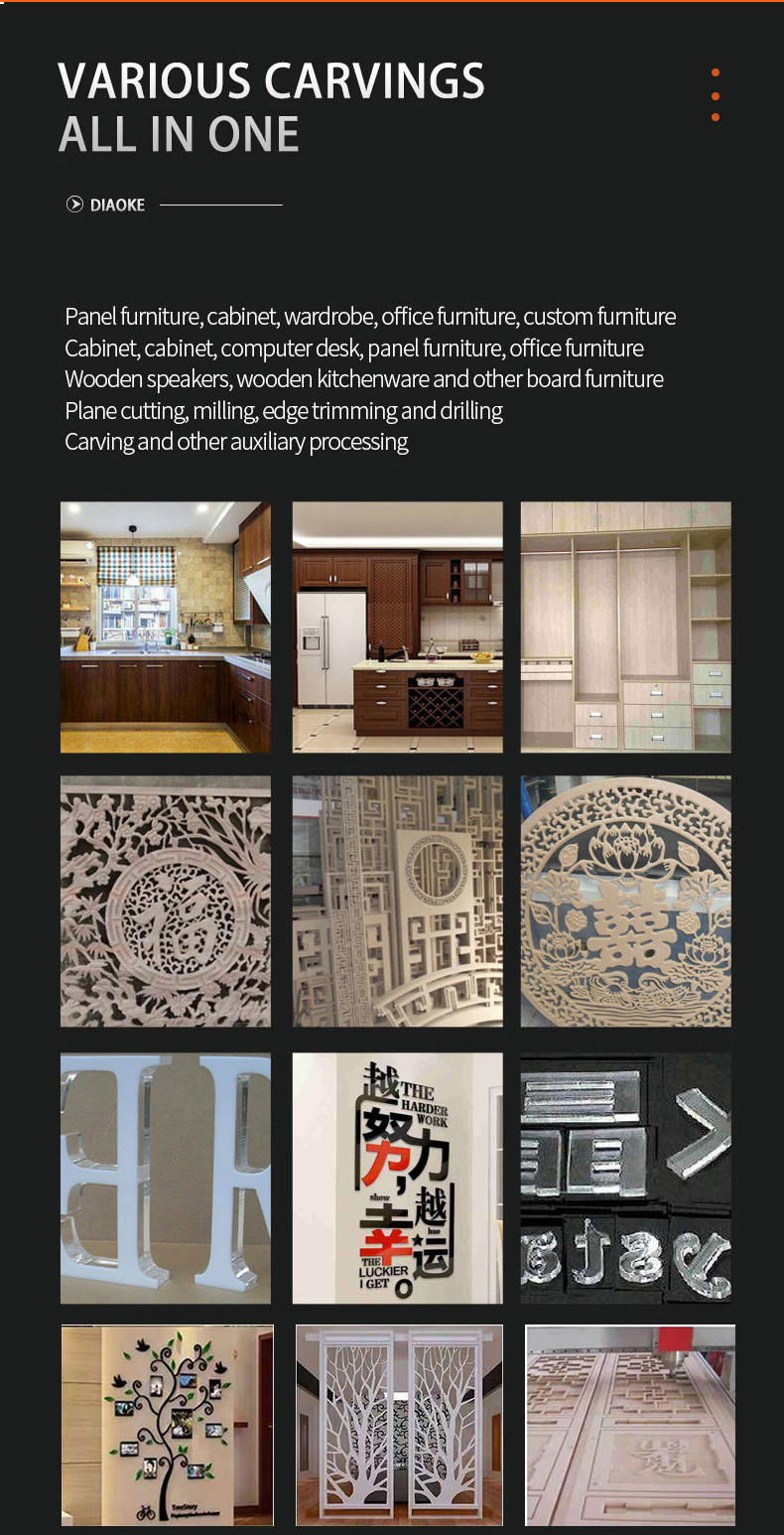

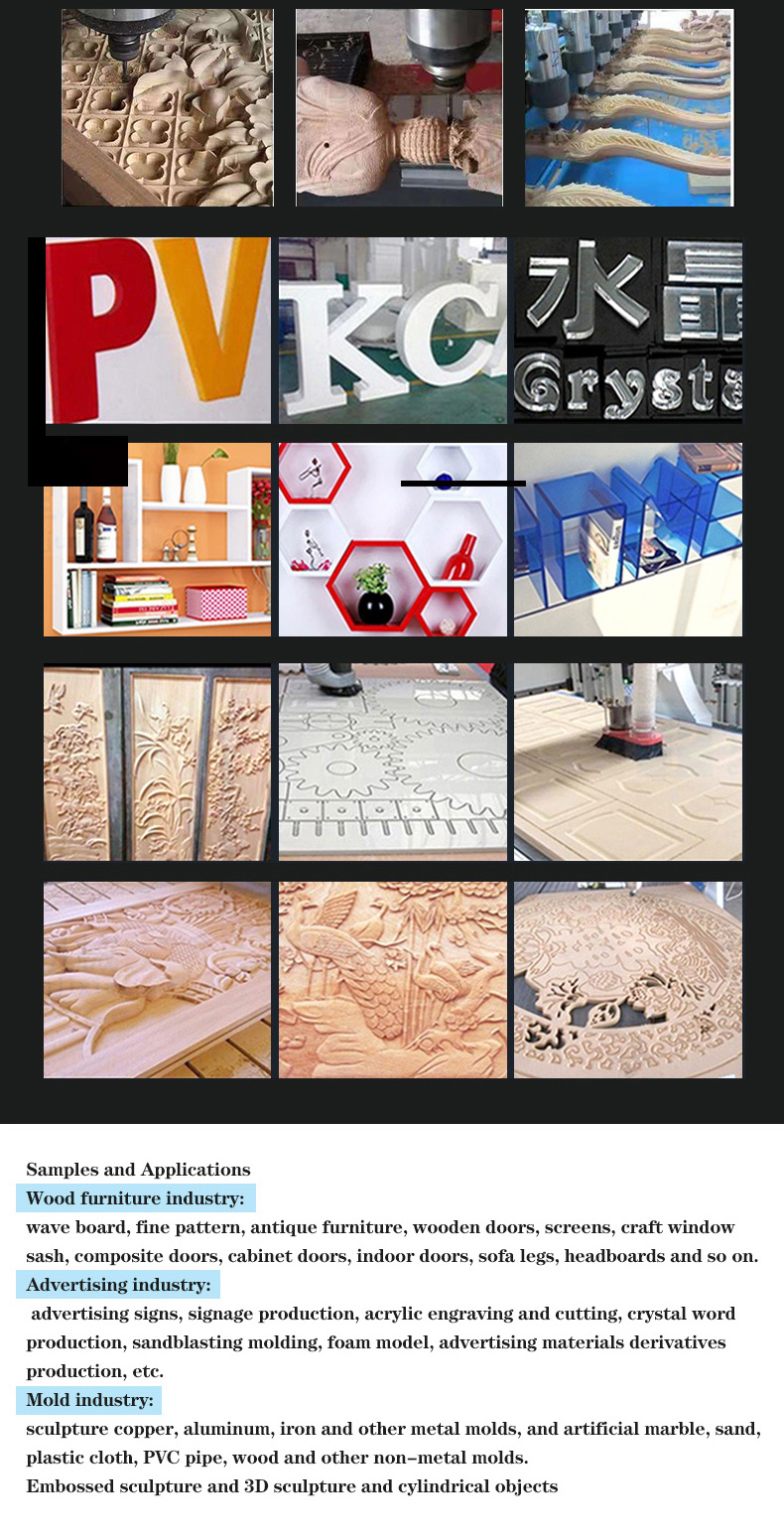

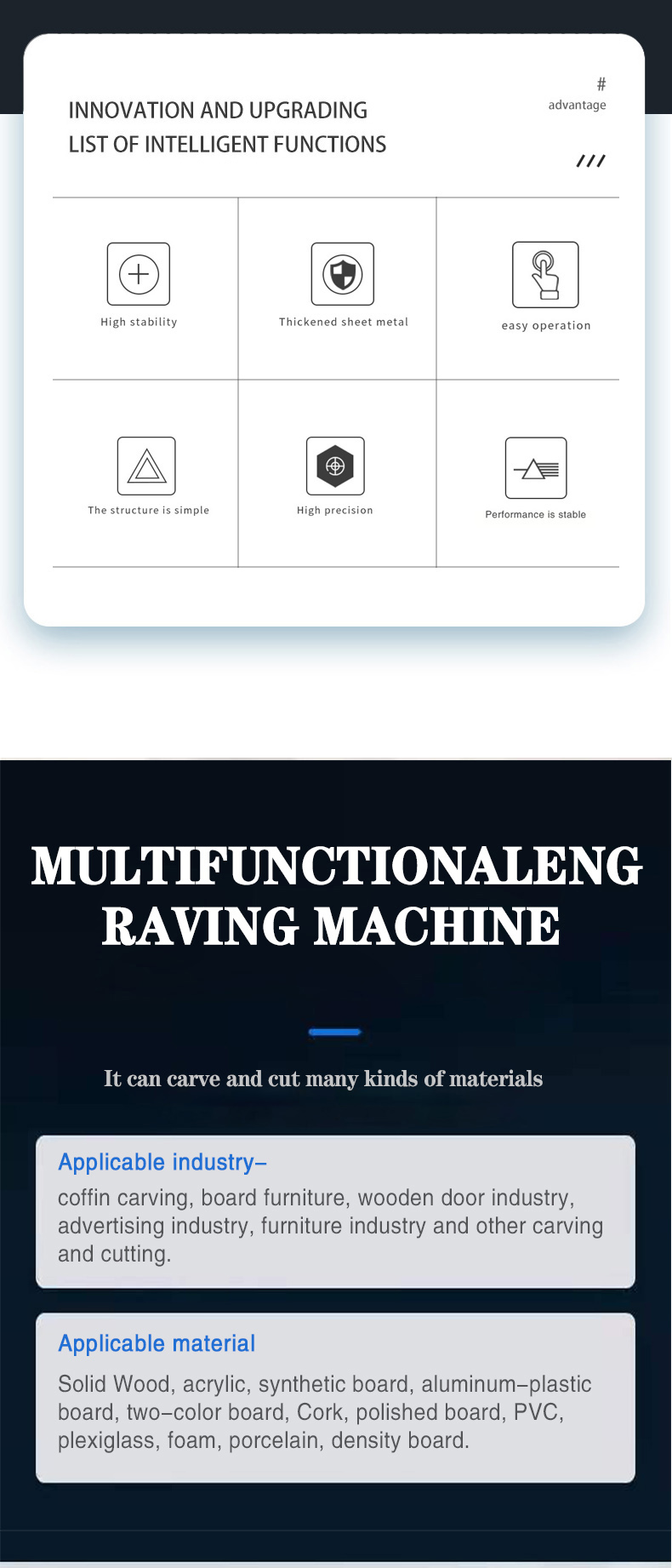

Main features

1.three axis adopts high precision ball screw, imported guide rail,to ensure the machine precision.

2. Use high subdivision step motor,high speed,low noise,stable operation,large cutting torque.

3.high power spindle motor with variable frequency brushless water cooling ,low noise,long life and uniform speed.

4.high power,deep cutting,can cut 2mm thickness acrylic sheet one time cutting (≥2.2KW)

5.open software interface,can be connected with various software 3D engraving software compatible.

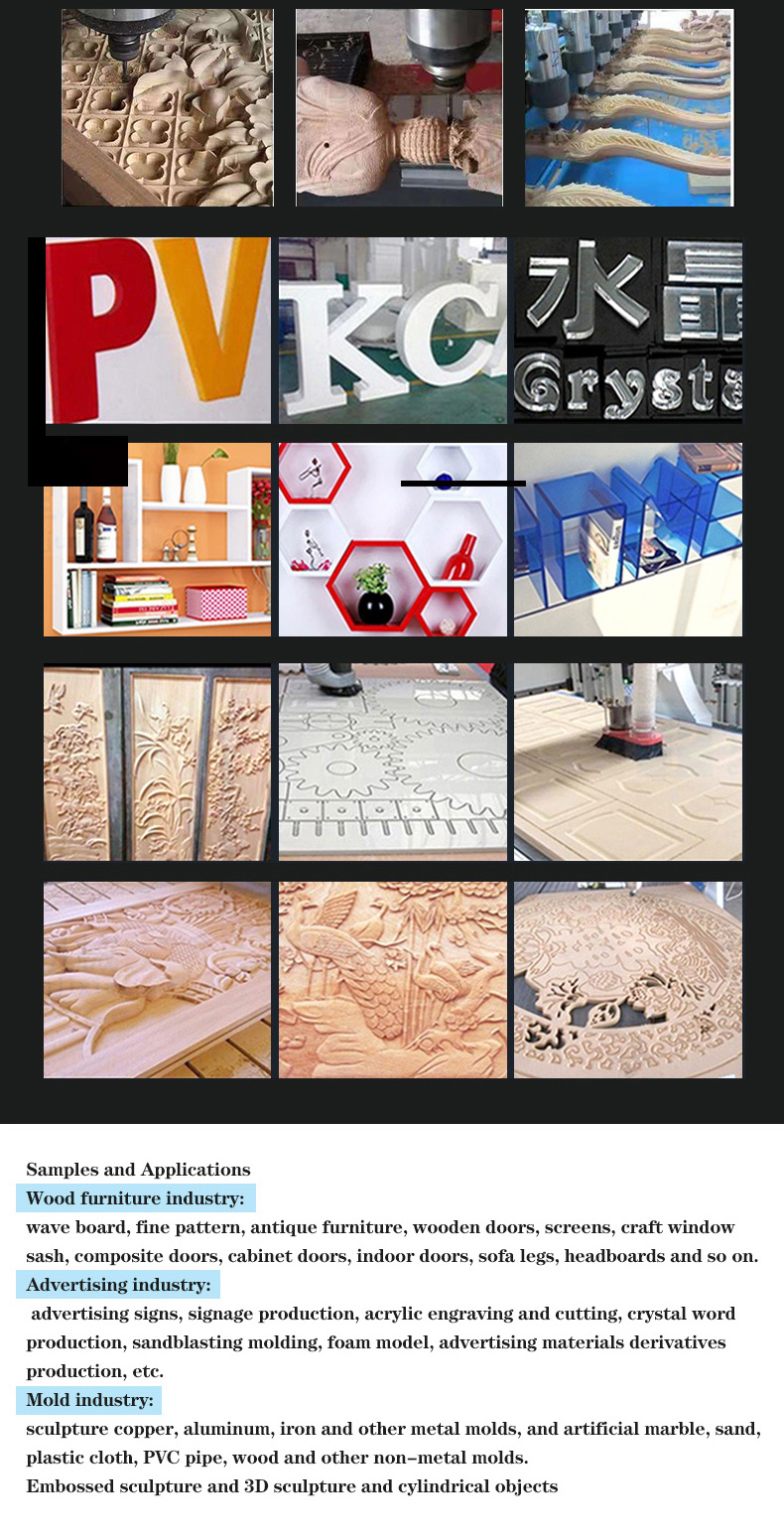

6. can be processed jade ,marble,granite artifical stone,ceramic ,tile, glass,aluminum and so on.

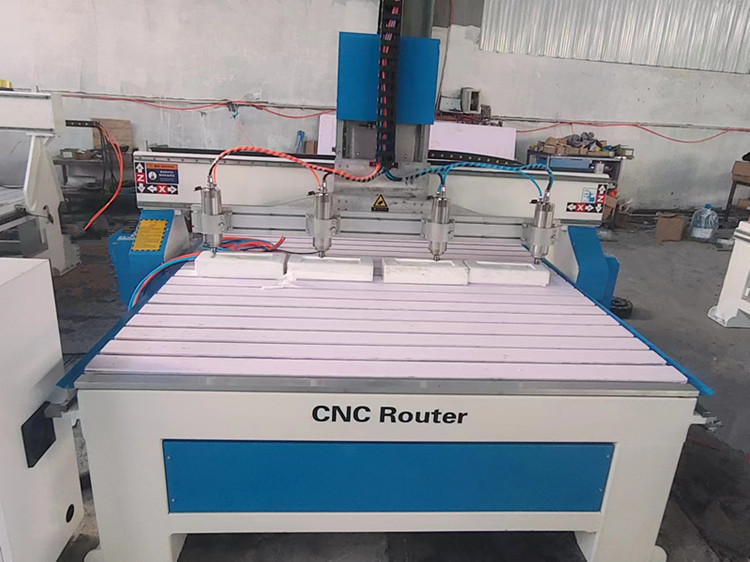

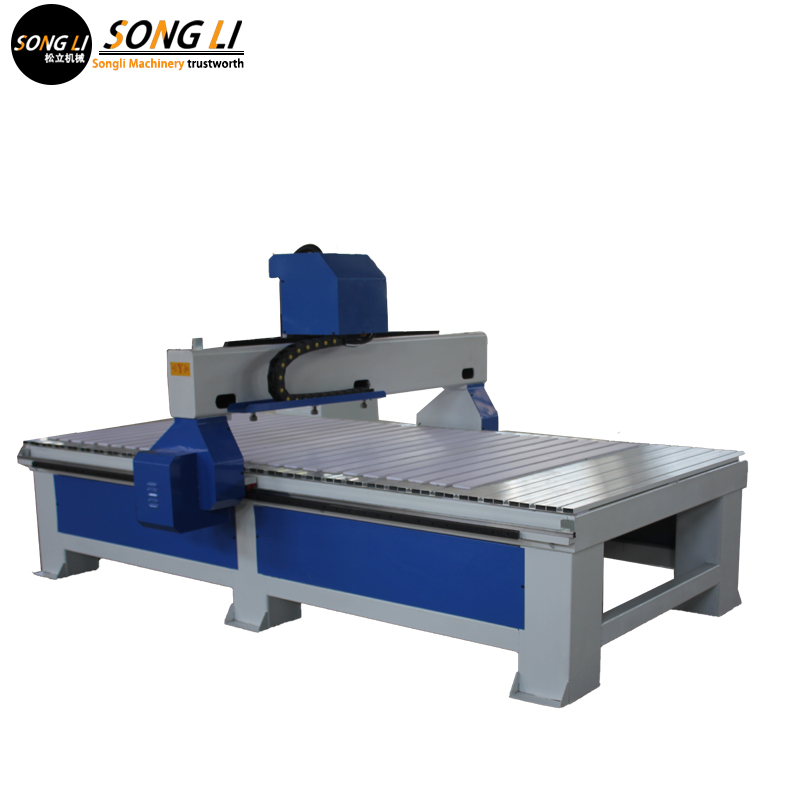

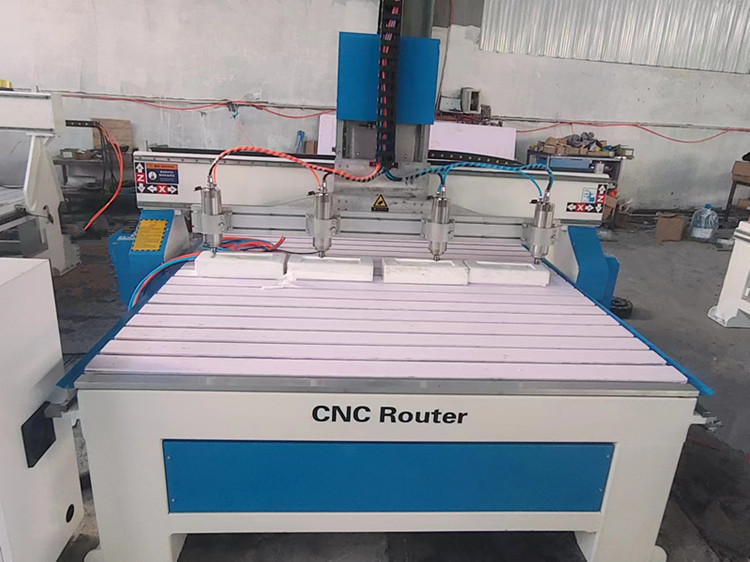

Real Pictures

Technical Parameters |

Principal axis | Water-cooled 3.0KW |

Dimension | 3100*2000*1600mm |

Working voltage | 380V |

Processing area | 1300*2500mm/Can be customize |

| Work platform | Welding 4mm Steel platform |

XYZ stroke | 1300*2500*200mm |

Machining precision | ±0.03mm (Less than 0.03mm) |

Repeated position accuracy | ±0.02mm |

Longmen structure | Thickened square steel gantry |

Basement | 0.5 seamless welding quenching treatment |

Operation mode | 86HBM80 hybrid servo motor |

Driver | Type 860 driver |

XYZ structure | X shaft slanting rack, Y shaft slanting rack, Z axis screw(+25 square rail) |

X/Y axis | 25 square rail/ helical rack |

Z axis | High precision TBI ball screw |

Certificates | CE |

Engraving instruction | HCP/G |

Operating system | NCStudio system |

Services:

· All of our machine will be full-checked and tested by our quality control department before shipment.

· Lifetime technology maintenance in free and spare parts supply.

· Free training. our engineer can speak English.

· 24 hours technical supported.

· We will offer ‘instruction books’, “Operation Manual” and “Training Video” to you. Which is easily understand.

· We also will offer online face by face training, from our special software, our engineer can control machine computer and machine to show you step by step.